The manufacturer of sandwich panels in Turkmenistan, «Ayly Shohle», has mastered the production of new types. «Ayly Shohle» ES purchased equipment for the production of sandwich panels: they are three-layer polyurethane foam (PUR) and polyisocyanurate foam (PIR).

At this time, the equipment has been installed by specialists from foreign countries and is ready for production. The production base is located in Ashgabat. Production capacity 60-80 thousand m2 of products per month. The shop has 5 workers per shift.

Sandwich Panels have a very low coefficient of thermal conductivity, light weight due to low density (insulation density does not exceed 45 kg/m3), high strength and performance characteristics. Sandwich panels are used for insulation of buildings and other structures, as well as for the construction of prefabricated frame buildings for various purposes.

Sandwich panels are characterized by high biological resistance and low water absorption. The chemical resistance of building materials to the effects of toxic substances makes them literally indispensable for the construction of facilities for the storage of toxic chemicals. The panels retain their structure under the most severe operating conditions, do not deform, and the service life is comparable to the service life of the building itself. In addition to thermal insulation properties, the panels have good soundproofing characteristics, reducing the noise level to 35 decibels.

Polyisocyanurate chars during combustion and prevents further combustion of the polymer. Thus, sandwich panels are distinguished by high fire-resistant characteristics. The temperature of their operation can reach up to 140°C. They have excellent moisture-resistant characteristics and are practically vapor-tight.

Sandwich panels are easy to install due to convenient locking connections and low weight. One panel, depending on its thickness, weighs from 9 and a half kilograms to 16. The use in the construction of panels allows you to build buildings several times faster than traditional methods (brick, etc.) at any time of the year, regardless of temperature. The panels are attached to the installed metal frame.

Panel advantages:

- mechanical strength,

- environmental friendliness,

- low coefficient of thermal conductivity is 0.022 W/mK,

- low water absorption,

- high fire resistance,

- chemical resistance,

-durability.

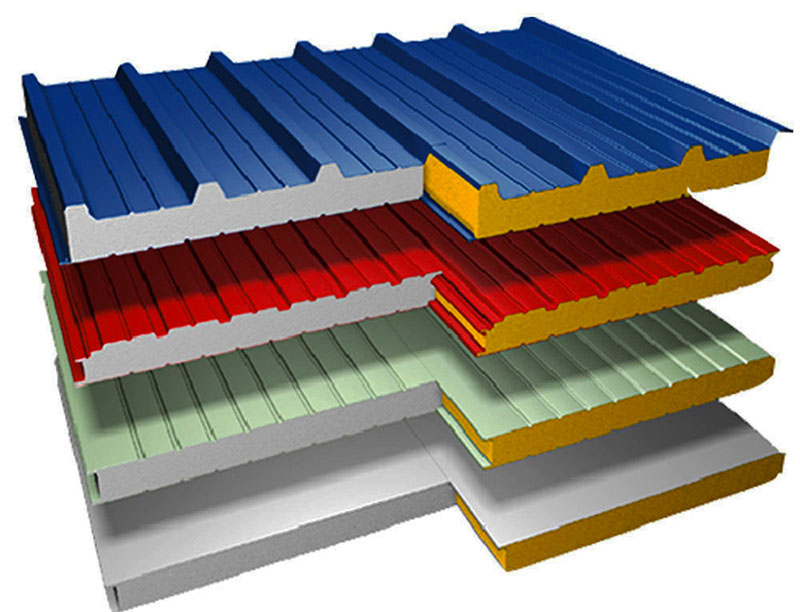

The panels are produced in wall and roof versions, differ in thickness from 50 to 100 mm, length from 3 to 12 meters, width 1 m. The panels have a Z-lock connection or a Hidden screw connection.

The surface of the panels can be smooth, ribbed, or it can be different on both sides: on the one hand, have stiffening ribs in the form of trapezoidal protrusions, and on the other, a microprofile.

As metal sides, cold-rolled steel with a thickness of 0.5-0.7 mm is usually used, either painted or covered with a plastic coating on top.

Also, our company has launched the production of metal tiles (1m wide, up to 10m long) to cover buildings and structures.